Value-added logistics (VAL) encompasses a range of services that logistics providers can offer to deliver more value to their clients. From repackaging and assembling to specialised processes like blast-freezing or blending, these services help differentiate you in the marketplace.

Blending is one such service, particularly for bulk goods or liquids like juices. Often, customers expect different products to be combined into a new, unique blend.

In 3PL Dynamics, this is handled seamlessly through the dedicated VAL module. Let’s explore how blending works within this system and the key challenges involved.

Key Challenges in the Blending Process

Incorporating blending into your logistics operations can be complex. A reliable software solution is crucial for avoiding mistakes.

Below, we’ve highlighted three common challenges you may encounter during blending and how 3PL Dynamics helps address them.

1. Managing Waste Products

When blending liquids, it’s inevitable that some of the product will be lost. Accurate tracking of this waste is essential to maintain correct inventory levels. For instance, you may need to adjust the inventory based on weight discrepancies.

In 3PL Dynamics, a scanning function can easily be configured to register waste and ensure your inventory remains precise.

2. Inventory Management

During the blending process, products are taken from the customer’s stock in your system. While these items are in production, they are temporarily removed from storage, which can impact storage fees.

If the blending process spans multiple days, this can significantly affect invoicing. With 3PL Dynamics, you have complete control over this aspect, ensuring transparency for you and your customer.

3. Recording Lab Values

If lab values are part of your process, you’ll need a way to track and document them by batch. 3PL Dynamics allows you to capture and link lab data directly to specific batches, ensuring you can always retrieve the necessary information easily.

How Blending Works in 3PL Dynamics

Within 3PL Dynamics, there are two primary methods for blending: recipe-based blending or blending based on customer demand.

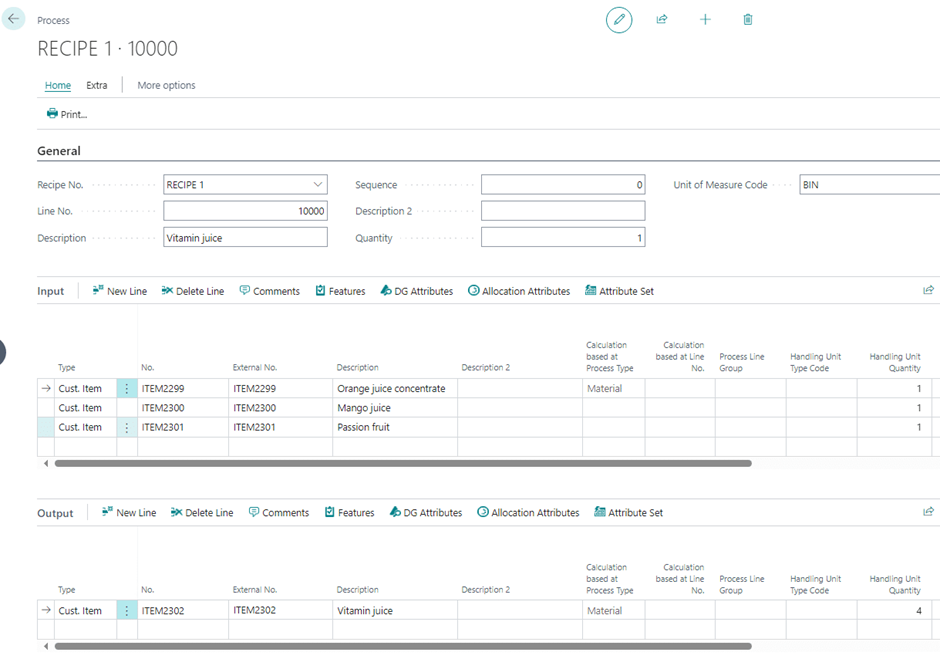

The system follows a pre-defined recipe to combine different customer products in recipe-based blending, as shown in the example below. The result is automatically generated by the VAL order within the system.

On the other hand, when blending based on customer demand, the recipe may vary, often being set to ‘Manual.’ This is common when a fixed recipe is not feasible, such as in juice production.

The taste of oranges, for instance, can vary throughout the year, so the blending process adjusts each time accordingly to achieve the desired consistency in flavour.

Post-Blending System Process

Once the VAL order is completed, the system deducts the necessary amounts from one or more customer products.

It adds them to a new product, maintaining a clear record of your inventory. This ensures you always have accurate control over stock levels, even after blending.

Adding Value through VAL Activities

Blending is just one of many value-added logistics services you can offer. Today, Logistics providers often become an integral part of their customers’ production process, even handling returns management in e-fulfilment.

Offering these services relieves pressure on your customers and sets you apart from the competition. Discover how value-added services like blending can enhance your logistics offering and boost your competitive edge.

Are you ready to elevate your logistics offerings and provide unparalleled value to your clients?

Discover how the 3PL Dynamics Value-Added Logistics (VAL) module can improve complex processes like blending, ensuring accuracy and efficiency in every step.

Whether you’re dealing with recipe-based blending or custom blends based on fluctuating customer demands, our solution offers precise waste management, transparent inventory control, and seamless lab value tracking.

Don’t let blending complexities slow you down—unlock the full potential of your logistics operations with 3PL Dynamics.

Contact us today to explore how our tailored solutions can optimise your workflows and deliver exceptional results for your clients!