Count

Optimise your inventory counting with the count feature in mobile WMS

Count

Is counting your inventory a resource-intensive task? Perhaps, you are still doing your counting based on “pen and paper”?

Counting based on pen and paper is typically done by manually performing the count, taking note of the counted quantity on physically printed lists, and then finally entering the data into the financial system. This process requires a high number of man-hours and is often error-prone.

Many companies perform counts multiple times over the course of a year. Changing to an automated method of handling your counts provides numerous benefits to you and your business.

Count in Mobile WMS supports:

Planned Count for Physical Inventory Counts and Unplanned Count for Ad-Hoc Counting

Mobile WMS offers two types of counts: ‘Planned Count’, which is typically your physical inventory count, and ‘Unplanned Count’, which is often used for ad-hoc counting.

You can perform your warehouse counts in different ways. In some situations, you will likely want to count the entire warehouse, while in other circumstances you might simply be looking to count a single bin, row, or item. The choice is yours.

When the physical inventory journal has been set up in your financial system, you will choose the type of count you would like to perform. The journal will then be released to the scanner. At that time, the warehouse employee can select the released physical inventory journal and start the actual count procedure.

Validating Counts

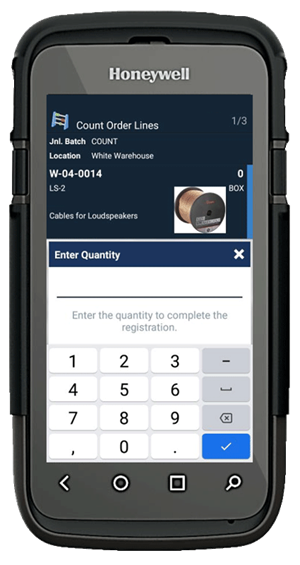

Per default, our solution is set up so that the count will be performed as a “blind count”. The person doing the count will therefore not be informed of the expected quantity of a particular item, which makes it necessary to count before the quantity is entered. The solution is, however, set up to offer the flexibility of being able to change that format. Through a small customization of the setup, the expected quantity can therefore be shown on the scanner prior to the count.

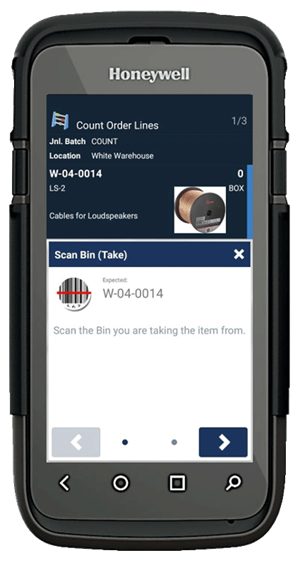

Mobile WMS makes certain that the performed count is validated based on a requirement to scan the bin as well as the item barcode.

When the count is finalized on the scanner, the registrations are transferred to the physical inventory journal in the financial system. If relevant, it is then possible to request a recount before finally posting the count.

If during your count, an unexpected item that is not on your physical inventory journal occurs, you are able to add this item to the journal.

Errors related to a manual counting procedure are very resource-intensive and costly. With Mobile WMS you can ensure that the count is validated and that you maintain a high inventory accuracy rate.